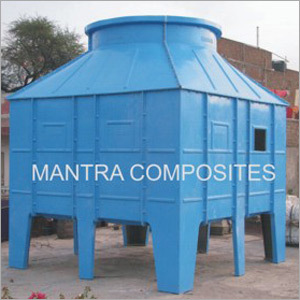

FRP Cooling Tower

FRP Cooling Tower Specification

- Density

- 1.9 Gram per cubic centimeter(g/cm3)

- Thickness

- 5-10 mm (Standard panel thickness)

- Shape

- Rectangular / Square

- Usage & Applications

- Process cooling, Air conditioning systems, Water cooling circuits

- Glass Type

- E-Glass

- GSM

- 300-900 GSM

- Thermal Conductivity

- 0.25 W/mK

- Coating Type

- Epoxy based corrosion resistant

- Temperature

- Operating range: -10C to +70C

- Material

- FRP (Fiberglass Reinforced Plastic)

- Application

- Industrial cooling for HVAC, power plants, chemical processes

- Technique

- FRP (Fiberglass Reinforced Plastic) Moulding and Fabrication

- Surface Treatment

- UV Protected, Anti-Corrosive Coating

- Dimension (L*W*H)

- 1200 mm x 1200 mm x 1800 mm (example standard size)

- Weight

- 80 kg to 700 kg depending on capacity

- Maintenance

- Low, easy access for cleaning and replacement

- Filling Type

- Splash/Film Fill Media

- Color

- Standard Blue / Custom Color Available

- Inlet/Outlet Size

- 50 mm to 250 mm

- Mounting Type

- Floor standing

- Capacity Range

- 10 TR to 2000 TR

- Water Distribution

- Rotary sprinkler system

- Service Life

- 10+ years under standard conditions

- Fan Type

- Corrosion-Resistant FRP Axial Fan

- Frame Structure

- Heavy-duty FRP/PVC support frame

- Motor Power

- 0.5 HP to 15 HP depending on model

- Flow Rate

- 15 m³/hr to 500 m³/hr

- Noise Level

- Below 70 dB

FRP Cooling Tower Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 100 Tons Per Month

- Delivery Time

- 1 Week

About FRP Cooling Tower

Owing to our vast industry experience, we are offering well build quality FRP Cooling Tower to our respected clients. The offered fiber reinforced plastic cooling towers are heat rejection devices, which are used to prevent the liquid from unwanted heat of outer atmosphere. Our supplied fiber reinforced plastic cooling towers employ the cold water stream for cooling process. The manufactured fiber reinforced FRP Cooling Tower are capable of cooling the water in short duration.

Features:

-

High strength

-

Corrosion proof

- Easy to install

Durability Meets Performance

Built with FRP materials and advanced fabrication techniques, these cooling towers are designed to withstand demanding industrial environments. The anti-corrosive, UV-protected exterior, combined with heavy-duty support frames, ensures long-lasting service and minimal deterioration, making them well-suited for outdoor installation.

Versatile Application Range

Suitable for process cooling, water circulation, and air conditioning systems, these cooling towers serve diverse sectors. With a wide operational temperature range and customizable configurations, users can rely on efficient, targeted cooling that adapts to various industrial requirements.

Efficient Operation and Easy Maintenance

Each tower features a rotary sprinkler water distribution system and FRP axial fans that maximize performance while maintaining low noise levels. The design facilitates easy access for inspection, cleaning, or component replacement, ensuring prolonged service life and lower maintenance costs for users.

FAQs of FRP Cooling Tower:

Q: How does the FRP cooling tower ensure long-term durability in harsh environments?

A: The cooling tower is constructed using FRP (Fiberglass Reinforced Plastic) and features an epoxy-based anti-corrosive coating along with UV protection. This combination resists weathering, chemical exposure, and corrosion, providing a service life that exceeds ten years under standard operating conditions.Q: What are the typical applications and industries that benefit from this cooling tower?

A: These towers are widely used in industrial process cooling, HVAC systems, water cooling circuits, and air conditioning applications. Key industries include power plants, chemical processing units, and any facility requiring efficient heat dissipation and water cooling.Q: When should I consider choosing a custom color or specification for the cooling tower?

A: Custom colors or configurations are ideal for projects requiring specific branding, visual integration with existing infrastructure, or specialized operational needs. Manufacturers accommodate custom requests to match client requirements while maintaining performance standards.Q: Where can the FRP cooling tower be installed and what are the mounting specifications?

A: These towers are floor-standing units designed for installation on level surfaceseither outdoors or in designated indoor spacesthanks to their robust, heavy-duty FRP/PVC support frame. Their shape and size options allow for flexible placement according to site conditions.Q: What is the cooling process employed by the tower, and how is water distributed?

A: The tower uses a rotary sprinkler water distribution system to evenly disperse water over splash/film fill media. This improves heat exchange as air is drawn upward by a corrosion-resistant FRP axial fan, maximizing cooling efficiency for circulating water.Q: How straightforward is the maintenance process for this cooling tower model?

A: Maintenance is simple due to the towers accessible design. Components such as fill media and sprinklers can be reached easily for inspection, cleaning, or replacement, ensuring continuous, trouble-free operation and extended service intervals.Q: What are the key benefits of using a corrosion-resistant FRP axial fan in this cooling tower?

A: The corrosion-resistant FRP axial fan enhances durability and reliability, particularly in harsh or chemically aggressive environments. This ensures efficient airflow, maintains low noise levels (below 70 dB), and extends the overall lifespan of the cooling tower.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Products Category

FRP Storage Tank

Price 250000-700000 INR / Piece

Minimum Order Quantity : 1 Liter

Application : Industrial storage of chemicals, water, acids, and alkaline solutions

Surface Treatment : Smooth, UV Resistant Coating

Material : FRP (Fiber Reinforced Plastic)

Dimension (L*W*H) : Customized as per requirement

FRP Statues

Price 1000 INR / Piece

Minimum Order Quantity : 2 Feet

Application : Outdoor and Indoor Decoration, Parks, Gardens, Commercial Spaces

Surface Treatment : Smooth Finish, Painted with Weatherproof Coating

Material : Fiber Reinforced Plastic (FRP)

Dimension (L*W*H) : Custom Sizes Available (Example: 5ft x 2ft x 7ft)

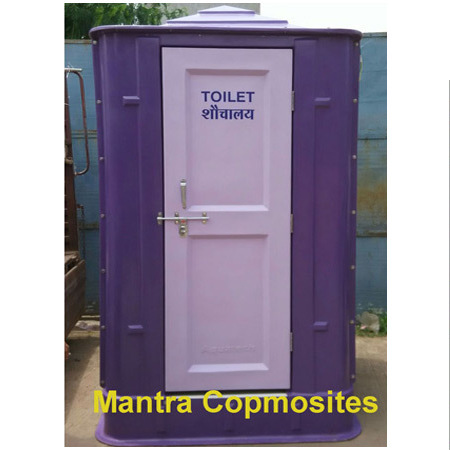

FRP Urinal

Minimum Order Quantity : 01 Piece

Application : Commercial & Public Toilets

Surface Treatment : Glossy Finish

Material : FRP (Fiberglass Reinforced Plastic)

Dimension (L*W*H) : 600mm x 400mm x 1200mm

FRP Bathroom

Minimum Order Quantity : 1 Piece

Application : Prefabricated modular bathroom unit, ideal for residential, commercial, and site accommodations

Surface Treatment : Smooth gel coat finish

Material : Fiberglass Reinforced Plastic (FRP)

Dimension (L*W*H) : Approx. 6 ft x 4 ft x 7 ft

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free